A unique combination of sizes and formulations for truly customized products.

| Product Type | Width Range | Length Range |

|---|---|---|

| Lay flat Bags – Individual | 4″ to 40″ | 6″ to 60″ |

| Lay flat Bags Perfed on the Roll (POR) | 4″ to 98″ | 6″+ |

| Gusseted Bags – Individual | W+D=Max 120″ | 4″ to 60″ |

| Gusseted Bags Perfed on the Roll (POR) | W+D=Max 120″ | 6″+ |

| Tubing – Continuous | 6″ to 98″ | Varies by Mil |

| Single Wound Sheeting | 6″ to 98″ | Varies by Mil |

| Sheets on the Roll | 6″ to 98″ | 6″+ |

| 3 Layer Bags & Film | 13″ to 85″ | Ind: Up to 60″, POR: 15″+ |

| 5 Layer Bags & Film | 24″ to 48″ | Ind: Up to 60″, POR: 15″+ |

Resins

- Linear Low Density Polyethylene – LLDPE

- Low Density Polyethylene – LDPE

- Medium Density Polyethylene – MDPE

- High Density Polyethylene – HDPE

- Metallocene Linear Low Density – MLLDPE

- Ethylene Vinyl Acetate – EVA

- Ethylene Vinyl Alcohol – EVOH

- Nylon – PA

Additives

- Anti-Stat

- Tint and Opaque Colors

- VCI (Volatile Corrosion Inhibitors)

- UVI (Ultra Violet Light Inhibitors)

- Flame Retardants

Other Capabilities

- One Color Random Repeat Printing

- Venting

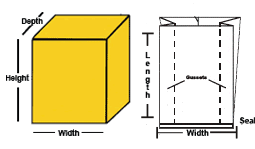

Gusseted Bags

Uses

- Box, bin, tote, gaylord liners, and top sheets / dustcovers

- Keeps finished product clean prior to shipping

- Protection from elements

- Pallet cover when inverted

- Dust and contamination protection of warehoused finished product

How To Select the Correct Bag Size

Width = Width + 4″

Gusset = Depth

Length: For a cover: Height + ½ Depth

For a liner: Height + Depth + 4″

| Product # | Width x Gusset x Length x Mil Description | Quantity Per Roll |

|---|---|---|

| PGB-F1340HNN-1007 | 54″ x 44″ x 96″ 2 mil tote liner | 50 |

How to Measure

Width x Length x Mil Thickness

How to determine bag size for object with depth

The gusset is considered to be the depth of the bag. For example, a 6″ x 3″ x 7″ bag would be 6 inches wide by 3 inches deep by 7 inches long.

Flat Polyethylene Tubing

- Make custom sized bags to protect piping, fluorescent light bulbs, carpet rolls, or any other long parts

- Made from a polyethylene blend that delivers the lowest cost and highest strength

- Available in 2 Mil or 4 Mil Thicknesses

- Low Minimum Orders (1 Roll)

2 Mil Uses

- Light Protection

- Custom Sized Bags

4 Mil Uses

- Greater Strength Protection

- Custom Sized Bags

2 Mil Products

| Product # | Width x Length X Mil Description |

|---|---|

| TUB-I1320HNN-1020 | 2″ x 2100′ x 2 mil clear |

| TUB-I1320HNN-1029 | 3″ x 2100′ x 2 mil clear |

| TUB-I1320HNN-1033 | 4″ x 2100′ x 2 mil clear |

| TUB-I1320HNN-1037 | 6″ x 2100′ x 2 mil clear |

| TUB-I1320HNN-1041 | 8″ x 2100′ x 2 mil clear |

| TUB-I1320HNN-1002 | 10″ x 2100′ x 2 mil clear |

| TUB-I1320HNN-1006 | 12″ x 2100′ x 2 mil clear |

| TUB-I1320HNN-1009 | 16″ x 2100′ x 2 mil clear |

| TUB-I1320HNN-1013 | 18″ x 2100′ x 2 mil clear |

| TUB-I1320HNN-1014 | 20″ x 2100′ x 2 mil clear |

| TUB-I1320HNN- 1016 | 24″ x 1050′ x 2 mil clear |

4 Mil Products

| Product # | Width x Length X Mil Description |

|---|---|

| TUB-I1320HNN-1019 | 2″ x 1050′ x 4 mil clear |

| TUB-I1320HNN-1003 | 3″ x 1050′ x 4 mil clear |

| TUB-I1320HNN-1031 | 4″ x 1050′ x 4 mil clear |

| TUB-I1340HNN-1035 | 6″ x 1050′ x 4 mil clear |

| TUB-I1340HNN-1036 | 8″ x 1050′ x 4 mil clear |

| TUB-I1340HNN-1043 | 9″ x 1050′ x 4 mil clear |

| TUB-I1340HNN-1002 | 10″ x 1050′ x 4 mil clear |

| TUB-I1340HNN-1006 | 12″ x 1050′ x 4 mil clear |

| TUB-I1340HNN-1013 | 16″ x 1050′ x 4 mil clear |

| TUB-I1340HNN-1016 | 18″ x 1050′ x 4 mil clear |

| TUB-I1340HNN- 1019 | 20″ x 1050′ x 4 mil clear |

| TUB-I1340HNN-1039 | 24″ x 525′ x 4 mil clear |

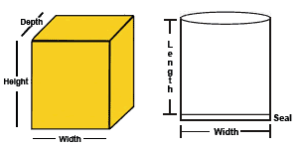

How to Measure

Width x Length x Mil Thickness

How to Measure Lay Flat Tubing

Lay flat Width = 1.57 x Diameter (round up to next size)

Other thicknesses are available with our custom manufacturing capabilities.

Food Storage Bags

Uses

- Dry Consumable Products

- Protect Foods Against Moisture and Dirt

Advantages

- DA Approved

- High Clarity

- Custom Sizes Available

| Product # | Width x Gusset x Length x Mil Description | Bags Per Case |

|---|---|---|

| IGB-F1001HNN-1024 | 5.5″ x 5″ x 16″ x 1 mil | 1000 |

| IGB-F1001HNN-1028 | 5.5″ x 5″ x 28″ x 1 mil | 1000 |

| IGB-F1001HNN-1039 | 8″ x 4″ x 20″ x 1 mil | 1000 |

| IGB-F1001HNN-1044 | 10″ x 8″ x 24 ” x 1 mil | 500 |

Individual Layflat Bags

- Variety of Sizes

- 2 Mil or 4 Mil Thickness

- Low Minimum Orders (1 Case)

2 Mil Uses

- Packaging small tools, parts, clothing, electronic equipment, and protecting food

4 Mil Uses

- Packaging bulky items

- Sharp edged objects

- Screws

- Nuts

- Bolts

- Heavier protection for Industrial parts & tools

2 Mil Products

| Product # | Width x Length X Mil Description | Bags Per Case |

|---|---|---|

| IBA-I1320-HNN-1067 | 3″ x 5″ x 2 mil | 1,000 |

| IBA-I1320-HNN-1001 | 4″ x 6″ x 2 mil | 1,000 |

| IBA-I1320-HNN-1077 | 5″ x 7″ x 2 mil | 1,000 |

| IBA-I1320-HNN-1091 | 6″ x 8″ x 2 mil | 1,000 |

| IBA-I1320-HNN-1095 | 8″ x 10″ x 2 mil | 1,000 |

| IBA-I1320-HNN-1044 | 10″ x 12″ x 2 mil | 1,000 |

| IBA-I1320-HNN-1002 | 12″ x 18″ x 2 mil | 1,000 |

| IBA-I1320-HNN-1039 | 16″ x 18″ x 2 mil | 500 |

| IBA-I1320-HNN-1110 | 18″ x 24″ x 2 mil | 500 |

| IBA-I1320-HNN-1116 | 20″ x 24″ x 2 mil | 500 |

| IBA-I1320-HNN-1051 | 24″ x 30″ x 2 mil | 250 |

| IBA-I1320-HNN-1119 | 30″ x 36″ x 2 mil | 250 |

4 Mil Products

| Product # | Width x Length X Mil Description | Bags Per Case |

|---|---|---|

| 0600484 | 3″ x 5″ x 4 mil | 1,000 |

| IBA-I1340-HNN-1027 | 4″ x 6″ x 4 mil | 1,000 |

| IBA-I1340-HNN-1079 | 5″ x 7″ x 4 mil | 1,000 |

| IBA-I1340-HNN-1033 | 6″ x 8 ” x 4 mil | 1,000 |

| IBA-I1340-HNN-1083 | 6″ x 10″ x 4 mil | 1,000 |

| IBA-I1340-HNN-1096 | 8″ x 10″ x 4 mil | 1,000 |

| IBA-I1340-HNN-1003 | 10″ x 12″ x 4 mil | 1,000 |

| IBA-I1340-HNN-1010 | 12″ x 18 ” x 4 mil | 500 |

| IBA-I1340-HNN-1038 | 18″ x 24″ x 4 mil | 250 |

| IBA-I1340-HNN-1040 | 20” x 24” x 4 mil | 250 |

| IBA-I1340-HNN-1022 | 24″ x 30″ x 4 mil | 150 |

| IBA-I1340-HNN-1005 | 30″ x 36″ x 4 mil | 100 |

How to Measure

Width x Length x Mil Thickness

How to determine bag size for object with depth

To determine width: Width + Depth + 1″

To determine Length:

If heat sealing: Height + Depth + 2″

If twist tying: Height+ Depth + 4″

Shrink Bundling Film

Wiman custom manufactures shrink bundling film to meet a variety of shrink needs. Whether you are packaging canned soups, boxed macaroni, or ice cream, Wiman can manufacture a shrink film that will give you excellent strength, clarity, and the shrinkage that is so important to your product’s image.

Custom shrink bags and folded sheeting is available for shrink tunnel applications as well as manual shrink applications using a heat gun.

| Thickness | Width Range | Minimum Order Size |

|---|---|---|

| 1 mil to 6 mil | 10” to 98” | 1000 LBS |

Vapor Corrosion Inhibitor (VCI)

Wiman’s VCI Series Vapor Corrosion Inhibitor (VCI) Packaging is a cost effective and proven corrosion protection product for basic corrosion protection. VCI is used for protecting metal components and equipment during storage, operations, and shipping. VCI is non-toxic, odorless, safe, environmentally friendly, easy-to-use, and does not leave any powder or flakes on metal surfaces being protected. Users of the Wiman VCI products reported that the product met their corrosion protection needs at a budget they can afford.

Product Availability

Wiman custom manufacturers VCI products to meet each individual customers needs. Whether you are looking for a small bag to package a metal part or are looking for a larger bag to cover equipment during shipment, Wiman VCI products will protect your product from being destroyed by corrosion. We look forward to helping you with your corrosion protection needs.

Wiman VCI products come in a variety of forms:

- Bags

- Tubing

- Sheeting